tips

Seed spacing interference is not displayed on the planter monitor. The only way to detect this problem while planting is to dig up seeds behind the row unit and check for spacing accuracy. Case IH does not currently offer factory attachments for liquid in-furrow product application. However, based on information supplied from customers who have had success applying liquid product in-furrow, we have outlined parameters for performing this operation with the least amount of interference. Please refer to the following information when advising customers of the risks involved with liquid in-furrow application attachments. Also, be sure to warn customers that digging seeds behind the planter row unit is the only sure method to determine planter seed spacing performance.

Two options for applying liquid product in-furrow with the Case IH row unit

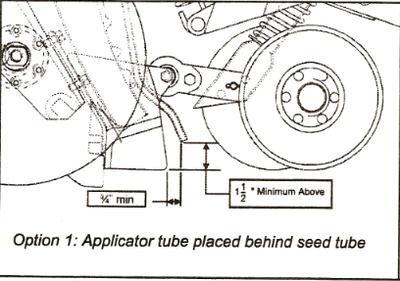

The Early Riser row unit can be used successfully with in-furrow liquid product by adhering to the following guidelines:

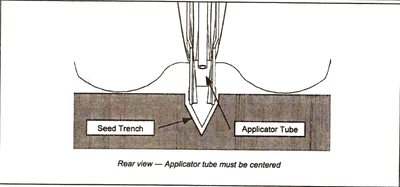

- Be careful to keep liquid residue from collecting inside the seed shoes or seed tube. If residue collects on either of these parts, the spacing performance from your planter will be affected. The product applicator tube must also be kept out of the path of seed delivery to the furrow.

- Keep the tip of the fertilizer tube at least one and one-half inch above the bottom of the seed shoe and at least 3/4 inch behind the rear corner of the seed shoe.

- Never use a spray applicator tip when placing liquid fertilizer in-furrow.

Liquid application attachments may cause poor seed spacing

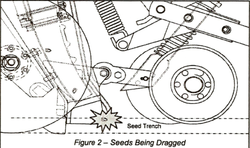

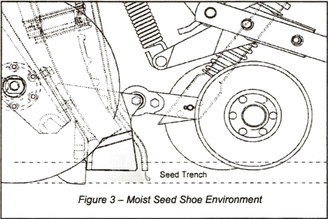

In recent years, there has been an increasing trend for growers to apply low rates of in-furrow liquid fertilizer and/or insecticide during the planting operation, particularly in corn. Many of these growers attach aftermarket or homemade application attachments to Case IH 1200 planters. They attempt to drop liquid product directly into the seed furrow before the closing disks begin sealing it. Many of these attachements are connect to what is commonly referred to as the “seed shoe” portion of the Case IH row unit (see Figure 1). The increase in customers who attempt to modify planters in this way has resulted in more customer seed spacing concerns. Case IH product specialists, along with members of the planter product development team, have investigated several such cases and have determined that such liquid fertilizer/insecticide application equipment can cause seed placement interference.

In some cases, seed is dragged by the attachment causing poor spacing (see Figure 2). In other cases, the attachment allows residue to accumulate around the seed shoe area, dragging the seeds off target.

In some cases, seed is dragged by the attachment causing poor spacing (see Figure 2). In other cases, the attachment allows residue to accumulate around the seed shoe area, dragging the seeds off target.

Saw Blade

It is important to remove the tip of down pressure closing disk tube, by cutting approximately 3/4″ of of it.